Chryssa Dimitriadis

Director Standard Management

IFS Management GmbH

IFS Management GmbH (IFS), owned by the retail associations HDE (Germany) and FCD (France), develops globally recognized product quality and safety standards and development programs for companies within the food and consumer goods supply chain companies. IFS comprises six different food and non-food standards and four development programs. These assess if private label and branded product suppliers can deliver safe, quality products in line with regulations and customer specifications. This way, IFS helps ensure that consumers can trust that the products they find on retail shelves are safe and of good quality.

IFS joined the International Accreditation Forum (IAF) as an Association Member in 2020, and in 2023 signed an agreement with IAF for the inclusion of its IFS Food standard in the IAF Multilateral Recognition Arrangement (MLA). The recognition of IFS Food as an IAF MLA sub-scope allows the acceptance of accredited certification to this scheme in multiple markets with only one accreditation, reducing costs and increasing value for businesses and consumers.

The IFS Food Standard

The IFS Food Standard applies to food processing companies and businesses that pack loose food products. It covers senior management responsibility, quality and food safety management systems including food defence, resource management, planning and production processes, measurements, analysis, and improvements. Suppliers certified to the standard find that the certification contributes to improving their business reputation, ensuring compliance with regulations, using resources more effectively, and fulfilling the prerequisites to supply those (retail) customers requiring third-party audits.

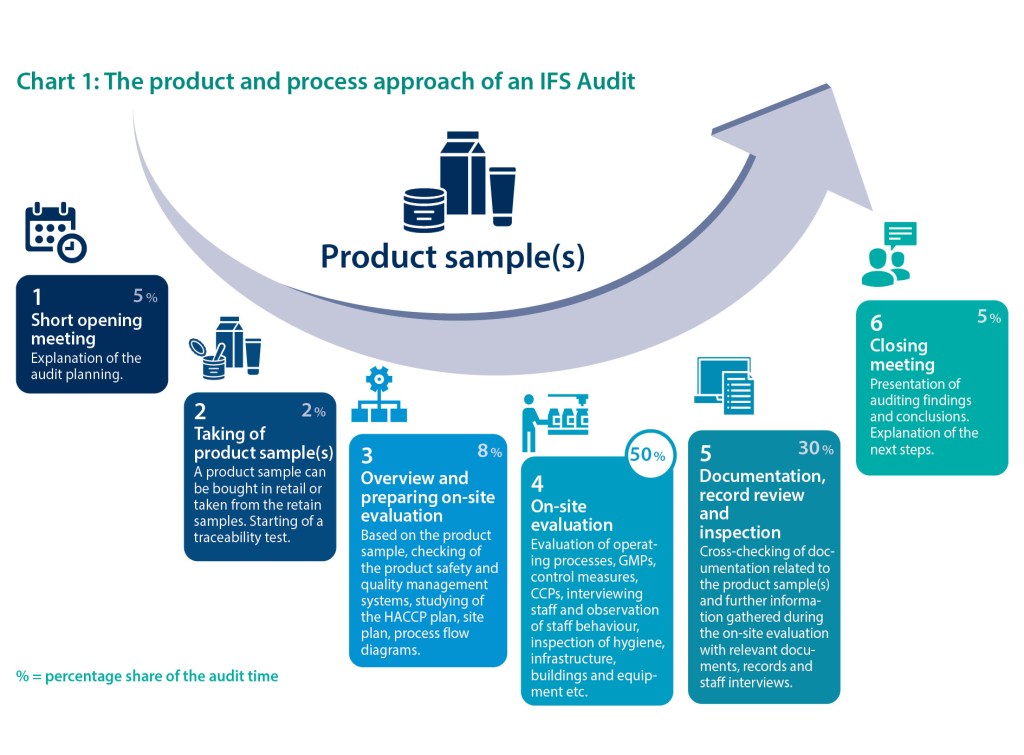

Pursuing a product and process approach

Following the ISO/IEC 17065 norm, the IFS Audit is product and process oriented. Based on the standard’s requirement an IFS-approved auditor checks if the company has established functioning, target-oriented and resilient processes to ensure the safety, legality and conformity with customer specifications of the products.

IFS pursues a vertical audit approach that follows the idea of good auditing practices. Before the audit, the auditor looks at the layout, processes, and hazard analysis and critical control points (HACCP) plans of the production site. On this basis, they check the products and related processes. This is accomplished through comprehensive product sampling, on-site inspection and assessment based on defined product and process requirements, as well as observations and interviews. The auditor consequently must spend sufficient time in the production area to gain a comprehensive overview of the company’s products, processes, and infrastructure.

The audit path

The general elements of an IFS Audit are:

1. Opening meeting

2. The evaluation of the status of the existing product safety and quality system achieved by checking documentation (HACCP, site plans, etc.)

3. On-site evaluation, operating process evaluation, observation and interviewing of the personnel, inspection of infrastructure, buildings, equipment, and staff behaviour

4. The cross-checking, inspection, and re-confirmation of gathered information during the on-site evaluation with relevant documents, records and staff and the auditing of the remaining documentation and management system elements

5. The final preparation of conclusions drawn from the audit

6. Closing meeting

During the IFS Audit, the IFS auditor collects objective evidence to be able to evaluate the compliance of the sampled products and the related operating processes with the audit requirements. This also includes the evaluation of compliance with further specific requirements, for example customer specifications and legal product safety compliance. To achieve this, the IFS auditor needs to apply different types of auditing and or inspection techniques, depending on the purpose of the evaluation.

One core feature of the IFS Audit is a continuous cross-check of information gathered by observation and interviews during the assessment of the standard’s requirements.

The continuous combination of documentation review and on-site evaluation allows the IFS auditor to conduct detailed inspection and verification activities and ultimately draw conclusions on compliance with the IFS Standard requirements including legal requirements and customer specifications.

Evaluating senior management commitment

One of the fundamental features of the IFS Audit is the active evaluation of the involvement and actions of the senior management. It is one of the 10 key objectives (KO) criteria in the standard and designed to check the commitment to food safety and establishing a product safety culture within the company. The senior management’s involvement usually is evaluated towards the end of the audit. The auditor then has collected enough samples, questions, and observations to discuss with the senior management. At this stage, the auditor presents – if any – the findings related to deficiencies in staff awareness and resources in regard to infrastructure and equipment found during the on-site evaluation.

Auditor qualification

IFS Audits are specific to detailed product and technology scopes as laid down in each IFS Standard. The IFS auditor’s scope specific expertise is a crucial basis for the IFS Audit. Accordingly, IFS checks the technical expertise and auditing experiences provided in the auditor’s CVs. Auditors need to pass a written and an oral exam before he or she is approved for performing IFS Audits.

Quality Assurance with IFS

It is important for IFS that all stakeholders can rely on the quality and credibility of the certificates issued. To ensure this, IFS initiated a quality assurance and Integrity Program in 2010, making us a pioneer in this field. Since then, we have constantly developed and improved it. In this regard, IFS investigates stakeholders’ complaints, monitors the performance of certification bodies and auditors and verifies that certified companies comply with the IFS Requirements.

Trusted standards for safe products and services

IFS Standards are uniform global safety and quality standards that provide transparency and comparability along the entire post-farm supply chain. Providing trusted standards and services to cooperate within the supply chain to improve product integrity is the goal that IFS strives for now and in the future.

Categories: IAF Members' news